So i have a new set of compoumds on my 12v. A k27 and an sxe369. Hungry diesel fuel pim, m&h timing space, 366 gov spring and hungry diesel lift pump. I have 5x14 injectors in it. I have done a few short test passes and its only pulling 30 lbs of boost. 1000° egts and very little smoke at wot. The star wheel is dropped all the way and the smoke screw is turned in alittle. The power screw is almost at its limit. I built 37lbs with my old hy35 and 5x12s. What are you guys with compounds runnin. Any help is appreciated!:grin2:

-

October's Cummins of the Month, Pumpkin Spice (fall / halloween), is now open for entries!

Injector sizing with compounds

93oneton

Discussion starter

1,059 posts

·

Joined 2014

- Add to quote

So i have a new set of compoumds on my 12v. A k27 and an sxe369. Hungry diesel fuel pim, m&h timing space, 366 gov spring and hungry diesel lift pump. I have 5x14 injectors in it. I have done a few short test passes and its only pulling 30 lbs of boost. 1000° egts and very little smoke at wot. The star wheel is dropped all the way and the smoke screw is turned in alittle. The power screw is almost at its limit. I built 37lbs with my old hy35 and 5x12s. What are you guys with compounds runnin. Any help is appreciated!:grin2:

29,796 posts

·

Joined 2010

Have you talked to Eric at HUNGRYDIESEL to see if he might be able to help you?

2,570 posts

·

Joined 2008

You should be able to make significant'y more boost than that with that fueling.

I'd be checking the wastegates and I'd also check to make sure your AFC is travelling like it is supposed to be.

I'd be checking the wastegates and I'd also check to make sure your AFC is travelling like it is supposed to be.

2,570 posts

·

Joined 2008

That's a hard answer to give. That answer depends on your fuel pin. IF you're only making 30psi and your afc is the culprit, you're afc is doing nothing most likely. Make sure the fuel pin is moving from boost pressure, if it is and you're not getting spring binding (if your star wheel is bottomed out, it won't be) Then the issue lies elsewhere.

Last question since it is relevant because you're running compounds: where is your boost gauge tapped in to?

Last question since it is relevant because you're running compounds: where is your boost gauge tapped in to?

93oneton

Discussion starter

1,059 posts

·

Joined 2014

The afc moves freely. What about removing the plastic spacer on the fuel pin. The wear mark shows its not gettin full movement.

My boost gauge is in the intake horn. So its measuring full boost.

My wastegate is set about 25 lbs. I tested it with my regulated air compressor

My boost gauge is in the intake horn. So its measuring full boost.

My wastegate is set about 25 lbs. I tested it with my regulated air compressor

2,570 posts

·

Joined 2008

nvm I misunderstood what you meant.

If it's not building boost very quickly, I would be looking at the wastegate.

Do both turbos have wastegates or just the secondary?

And what do you mean by stripped down?

If it's not building boost very quickly, I would be looking at the wastegate.

Do both turbos have wastegates or just the secondary?

And what do you mean by stripped down?

2,570 posts

·

Joined 2008

yeah I edited my post. you're quick in response

IT could be that it isn't getting full throttle any more, that could definitely cause the problem you're seeing.

I always throw that plastic ring that slides over the fuel pin away.

try tightening down the secondary gate and see what happens

IT could be that it isn't getting full throttle any more, that could definitely cause the problem you're seeing.

I always throw that plastic ring that slides over the fuel pin away.

try tightening down the secondary gate and see what happens

93oneton

Discussion starter

1,059 posts

·

Joined 2014

The k27 has the waste gate.yeah I edited my post. you're quick in response

IT could be that it isn't getting full throttle any more, that could definitely cause the problem you're seeing.

I always throw that plastic ring that slides over the fuel pin away.

Which turbo has the wastegate set at 25psi?

2,570 posts

·

Joined 2008

and what are the full specs on the s369? like what turbine wheel and housing is on it?

E: yeah I edited my post again because I sent it before your second response loaded on my page

E: yeah I edited my post again because I sent it before your second response loaded on my page

2,570 posts

·

Joined 2008

Well either way it's likely due to a lack of fueling. If the fuel pin is moving like it is supposed to be then it has to be something else. I would check to make sure you're getting full throttle. Are you certain the power screw is near runaway?

The video didn't post.

Is the tailpipe clean at wide open throttle?

Sent from my SM-G930W8 using Tapatalk

The video didn't post.

Is the tailpipe clean at wide open throttle?

Sent from my SM-G930W8 using Tapatalk

12,326 posts

·

Joined 2011

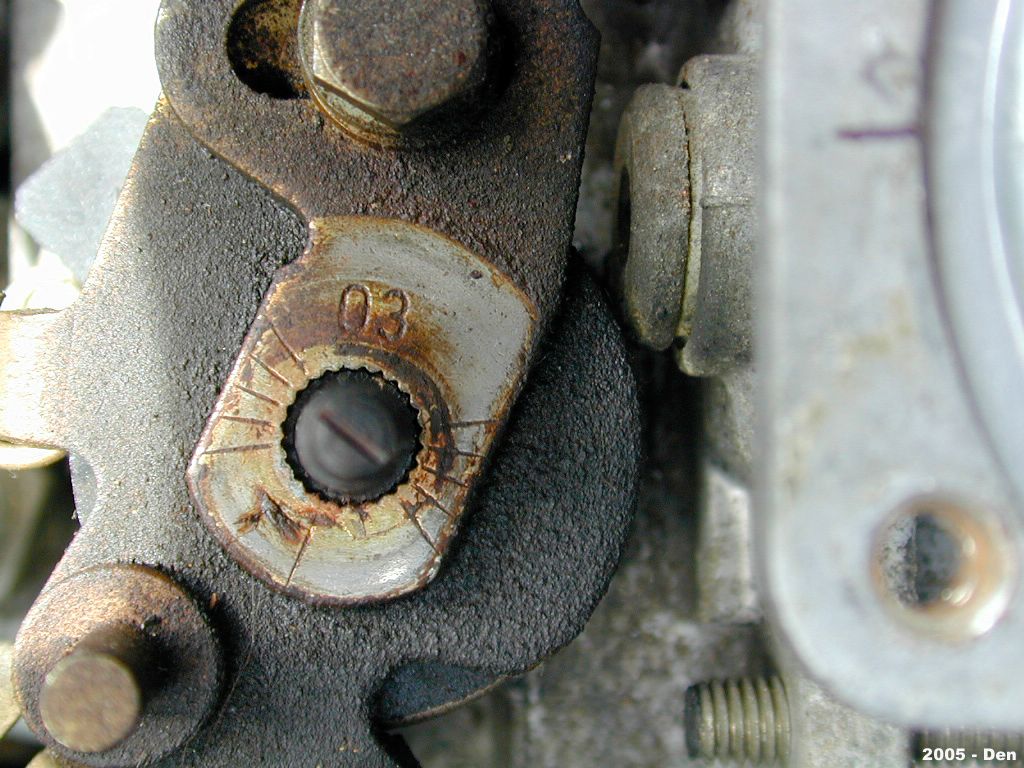

0:11-0:12... There's a drive pressure leak. Wouldn't hurt to get that taken care of.

You're getting some experienced help, so I have nothing to really add, but I have read that drive pressure and shop air are night and day difference. A gate can open way sooner than what it does with shop air. A member here had the same problem on his 2nd gen. He'd set the gate with shop air, but in reality the gate was opening way sooner, causing low boost.

Something to think about...

You're getting some experienced help, so I have nothing to really add, but I have read that drive pressure and shop air are night and day difference. A gate can open way sooner than what it does with shop air. A member here had the same problem on his 2nd gen. He'd set the gate with shop air, but in reality the gate was opening way sooner, causing low boost.

Something to think about...

6,965 posts

·

Joined 2013

All the 369sxe's I've seen have the updated 80/73 turbine wheel. It certainly sounds like a lack of fuel since your egts are so low. Lack of load would explain some of it, but not all of it.

My setup before I maxed my pump was netting 35psi overall, 20 from the primary, and hazed; now with the pump maxed I'm at 45, and 30, and it cleans all the way up. My primary is still doing almost all the work, but it does move decent.

My setup before I maxed my pump was netting 35psi overall, 20 from the primary, and hazed; now with the pump maxed I'm at 45, and 30, and it cleans all the way up. My primary is still doing almost all the work, but it does move decent.

2,570 posts

·

Joined 2008

It's idling low. I'm guessing you don't actually have a tach hooked up. It sounds like it's idling down around 5-600rpm. 650 tops. It needs to be up around 800

Nice build for sure though. I like that.

Turn the fuel screw in (make sure you have a board on hand for when it runs away) until runaway and then back it out 1/4 or 1/2 turn

If I had to take a stab at it, I'd guess your issue is the fuel screw wasn't put back where it was supposed to be after the GOV spring install

Throttle indexing won't necessarily change whether or not your getting full throttle. To check if you're getting full throttle you need to have someone in the cab push the pedal to the floor while you check to see if the throttle arm gets pulled all the way to the high idle (full throttle) stop on the pump.

Nice build for sure though. I like that.

Turn the fuel screw in (make sure you have a board on hand for when it runs away) until runaway and then back it out 1/4 or 1/2 turn

If I had to take a stab at it, I'd guess your issue is the fuel screw wasn't put back where it was supposed to be after the GOV spring install

Throttle indexing won't necessarily change whether or not your getting full throttle. To check if you're getting full throttle you need to have someone in the cab push the pedal to the floor while you check to see if the throttle arm gets pulled all the way to the high idle (full throttle) stop on the pump.

2,570 posts

·

Joined 2008

Leave the throttle indexing as-is. It's in the right spot. If it was wrong the truck wouldn't start if it was off one way, and if off the other way it would be idling way high at like 1500-2000rpm

For reference, this is 800rpm as shown by the tach on my dash when it first fires up

For reference, this is 800rpm as shown by the tach on my dash when it first fires up

2,570 posts

·

Joined 2008

At the moment, it is highly unlikely to be your problem but Will does make a very good point about the wastegate.

When it comes to setting a wastegate with shop air the one thing that isn't taken into consideration is the exhaust pressure trying to push the wastegate puck open. While the pressure inside the can with shop air may hold it shut at 20psi it's not taking into account the roughly 20psi of exhaust pressure also pushing on the pucks which is, in turn, pushing the rod on the can. This usually becomes an issue when people don't have enough tension on the turnbuckle for the wastegate so exhaust pressure overcomes the tension from the can and forces the gate open. This is typically a problem at higher boost pressures and with compound setups. It is also why many people opt to run spring gates instead on compound setups.

After you've sorted out your low boost problem and trying to dial in/tune your compounds, keep this in mind.

When it comes to setting a wastegate with shop air the one thing that isn't taken into consideration is the exhaust pressure trying to push the wastegate puck open. While the pressure inside the can with shop air may hold it shut at 20psi it's not taking into account the roughly 20psi of exhaust pressure also pushing on the pucks which is, in turn, pushing the rod on the can. This usually becomes an issue when people don't have enough tension on the turnbuckle for the wastegate so exhaust pressure overcomes the tension from the can and forces the gate open. This is typically a problem at higher boost pressures and with compound setups. It is also why many people opt to run spring gates instead on compound setups.

After you've sorted out your low boost problem and trying to dial in/tune your compounds, keep this in mind.

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 9M

- members

- 405K

- Since

- 2005

A forum community dedicated to all things Cummins Diesel! Originally founded for owners and enthusiasts of Cummins powered Dodge pickups, the Cummins Forum has expanded to include ALL Cummins Engine applications! Come join the discussion about reviews, drivetrain swaps, turbos, modifications, classifieds, builds, troubleshooting, maintenance, and more!

Our Vendors

View AllTop Contributors this Month

View All

camperman

251 Replies

gsbrockman

203 Replies

Max Tune

194 Replies